Top 10 Industrial Vending Machines for Efficient Inventory Management

The increasing complexity of supply chain management and the pursuit of operational efficiency have driven many industries to explore innovative solutions for inventory control. Among these, industrial vending machines have emerged as a transformative tool that not only optimizes inventory management but also enhances productivity by providing immediate access to essential items. According to a report by MarketsandMarkets, the industrial vending machine market is projected to reach USD 3.5 billion by 2025, growing at a remarkable CAGR of 8.5% from 2020. This growth reflects a significant shift in how companies manage their assets and materials, reducing the time spent on inventory tracking and procurement.

By automating the dispensing of maintenance, repair, and operations (MRO) supplies, industrial vending machines help minimize stockouts and reduce waste, contributing to a leaner operating environment. Furthermore, a study from the Aberdeen Group indicates that organizations implementing vending solutions have seen inventory carry costs decrease by up to 30%, while increasing tools and supplies availability by 45%. The efficiency gained through these machines not only streamlines the restocking process but also empowers employees on the shop floor, thus reshaping the conventional approach to inventory management. This article explores the top 10 industrial vending machines that are paving the way toward a more efficient and cost-effective inventory management strategy.

Overview of Industrial Vending Machines

Industrial vending machines have become a vital solution for efficient inventory management across various sectors. These automated systems are designed to store, dispense, and track a wide range of supplies and tools required in manufacturing and maintenance environments. By integrating technology into the inventory process, these machines help reduce waste, minimize downtime, and streamline operations. The convenience of accessing essential items on-demand ensures that employees can focus on their tasks rather than searching for equipment or supplies.

One of the key advantages of industrial vending machines is their ability to provide real-time data on inventory levels and usage patterns. This data-driven approach helps organizations maintain optimal stock levels and anticipate future needs, ultimately leading to better financial management. The machines can be programmed to alert management when stock is running low or when certain items are frequently requested, promoting proactive replenishment. Furthermore, these systems enhance security by restricting access to high-value items, ensuring that only authorized personnel can retrieve necessary supplies. The result is a more organized, efficient, and accountable inventory management process that supports overall business productivity.

Top 10 Industrial Vending Machines for Efficient Inventory Management

| Machine Model | Item Capacity | Connectivity | Inventory Management Features | Ideal Usage |

|---|---|---|---|---|

| Model A | 800 Items | Wi-Fi, Ethernet | Real-time tracking, Automated reports | Manufacturing Plants |

| Model B | 500 Items | Bluetooth, Cloud-based | Low stock alerts, Usage analytics | Warehouses |

| Model C | 1000 Items | Wi-Fi | Audit trails, Custom reporting | Construction Sites |

| Model D | 700 Items | Ethernet | Stock predictions, RFID integration | Factories |

| Model E | 600 Items | Wi-Fi, Bluetooth | Machine health monitoring, Remote access | Repair Shops |

| Model F | 900 Items | Cloud-based | Vendor-managed inventory, Data exports | Logistics |

| Model G | 800 Items | Ethernet, Bluetooth | Predictive analytics, User access control | Research Labs |

| Model H | 400 Items | Wi-Fi | Mobile app integration, Audit reports | Small Businesses |

| Model I | 1000 Items | Ethernet | Supply chain tracking, Multi-site management | Distribution Centers |

| Model J | 750 Items | Wi-Fi, Cloud-based | Custom alerts, Integration with ERP | Food Processing |

Key Features of Efficient Inventory Management Solutions

Efficient inventory management is crucial for industries seeking to streamline operations and reduce overhead costs. One of the key features of modern industrial vending machines is their ability to provide real-time data on inventory levels. This allows companies to monitor usage patterns and stock levels accurately, enabling them to make informed purchasing decisions. By integrating these machines with supply chain systems, businesses can automate reordering processes and minimize the risk of stockouts or excess inventory.

Another significant feature is the enhanced security that industrial vending machines offer. With access controls and user authentication, these systems ensure that only authorized personnel can withdraw items. This capability not only protects valuable assets but also provides detailed usage reports, which can help identify trends and optimize inventory allocation. Moreover, many machines are equipped with advanced tracking technology, such as RFID, allowing for precise item tracking and reducing the likelihood of loss or theft. These features collectively contribute to a more efficient and accountable inventory management strategy, fostering improved operational efficiency.

Top Industries Utilizing Industrial Vending Machines

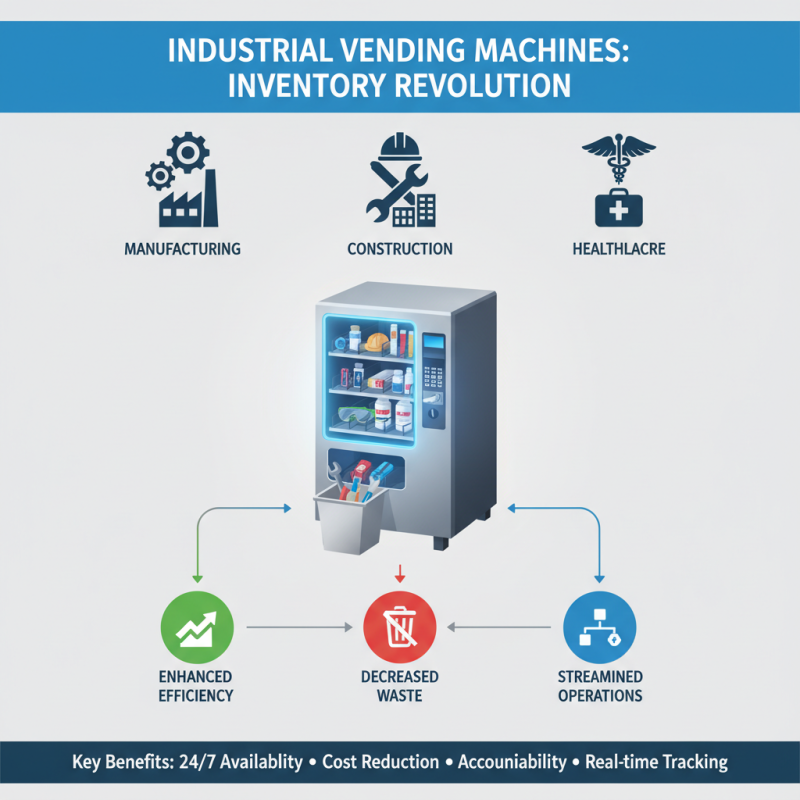

Industrial vending machines have revolutionized inventory management across various sectors. Many industries have recognized the benefits of implementing these machines to enhance efficiency, decrease waste, and streamline operations. Manufacturing, construction, and healthcare are among the top fields that utilize industrial vending machines to manage their inventory proficiently.

In manufacturing, these machines facilitate a just-in-time inventory approach, ensuring that tools and components are readily available when needed without excess stock. This reduces downtime and improves productivity. Similarly, the construction industry benefits from easy access to personal protective equipment and tools on-site, allowing workers to replenish supplies without delays. In the healthcare sector, vending machines provide essential medical supplies, ensuring that healthcare professionals have immediate access to the materials they require while also helping to control costs and monitor usage.

The versatility of industrial vending machines makes them an ideal solution for various industries seeking to optimize their inventory management. By implementing these systems, companies can maintain better control over their supplies, reduce losses, and improve overall efficiency, leading to a more organized and productive work environment.

Comparison of Leading Industrial Vending Machine Brands

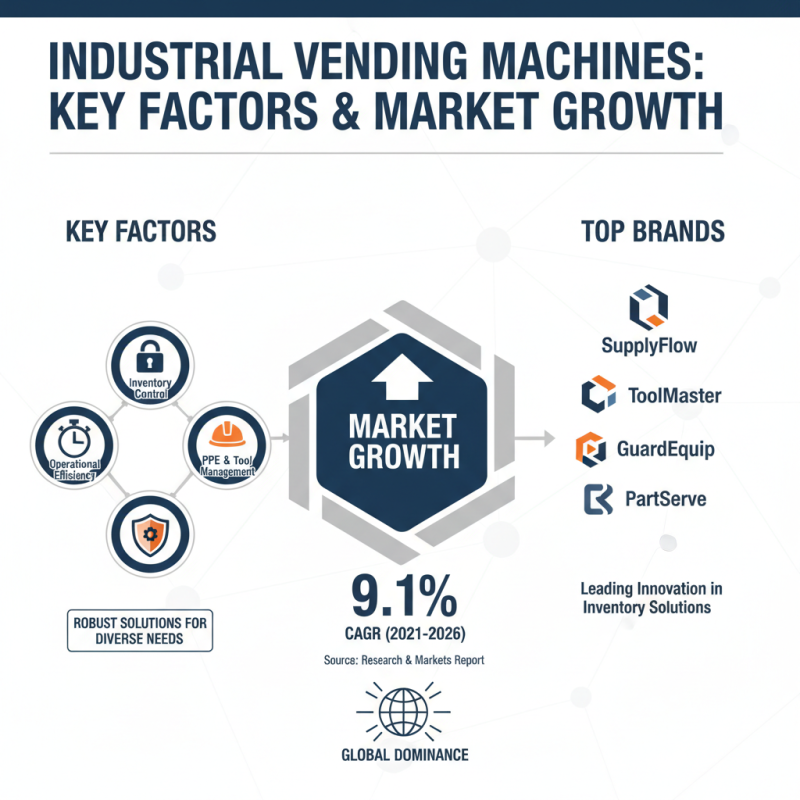

When evaluating the leading brands of industrial vending machines, several key factors emerge that significantly influence their effectiveness in inventory management. According to a market report from Research and Markets, the global industrial vending machine market is projected to grow at a CAGR of 9.1% from 2021 to 2026, driven by the increasing need for better inventory control and efficiency in operations. The top brands geographically dominate the market by offering robust vending solutions that cater to diverse industrial needs, from managing personal protective equipment (PPE) to tool and part dispensing.

A comparative analysis of these vending machine brands reveals notable differences in key performance indicators such as inventory tracking capabilities, ease of use, and integration with existing enterprise resource planning (ERP) systems. For instance, a report from MarketsandMarkets highlights that over 70% of companies implementing advanced vending solutions reported a decrease in inventory costs by as much as 30%, underscoring the financial benefits of choosing the right system. Furthermore, many brands now utilize IoT technology, enabling real-time monitoring and ensuring that stock levels are optimized to reduce downtime and inefficiencies on the shop floor. This technological evolution continues to shape the landscape of industrial vending, making an informed brand choice crucial for any organization looking to enhance its inventory management processes.

Benefits of Implementing Industrial Vending Machines in Warehouses

Implementing industrial vending machines in warehouses offers several significant benefits that enhance inventory management and operational efficiency. First and foremost, these machines provide a streamlined approach to accessing tools, supplies, and parts needed for daily operations. By allowing employees to quickly retrieve items without going through manual inventory checks, warehouses can significantly reduce downtime. This swift access not only boosts productivity but also ensures that staff can focus on their core tasks, rather than wasting time searching for essential materials.

Moreover, industrial vending machines help maintain optimal inventory levels through robust tracking systems. By monitoring usage patterns and automatically recording items dispensed, businesses gain valuable insights into consumption trends and inventory turnover rates. This data-driven approach enables managers to make informed decisions regarding reordering and stock levels, reducing the likelihood of overstocking or stockouts.

Furthermore, with the added benefit of enhanced security, these machines minimize loss or misuse of inventory, delivering a more controlled and accountable environment. Overall, the integration of industrial vending machines represents a smart investment in modern inventory management strategies, driving efficiency and cost-effectiveness in warehouse operations.

Related Posts

-

10 Tips for Choosing the Best Industrial Vending Machines for Your Business

-

How to Choose the Right Vending Solutions for Your Business Needs

-

Unlocking Efficiency with Industrial Vending Machines for Modern Manufacturing Solutions

-

2025 Top 10 Vending Machines Revolutionizing Convenience and Snacks

-

The Evolution of High End Vending Machines Revolutionizing Convenience and Innovation

-

12 Best Hot Drinks Vending Machines for Ultimate Beverage Convenience