Why Choose a Laboratory Sample Pulverizer for Your Needs?

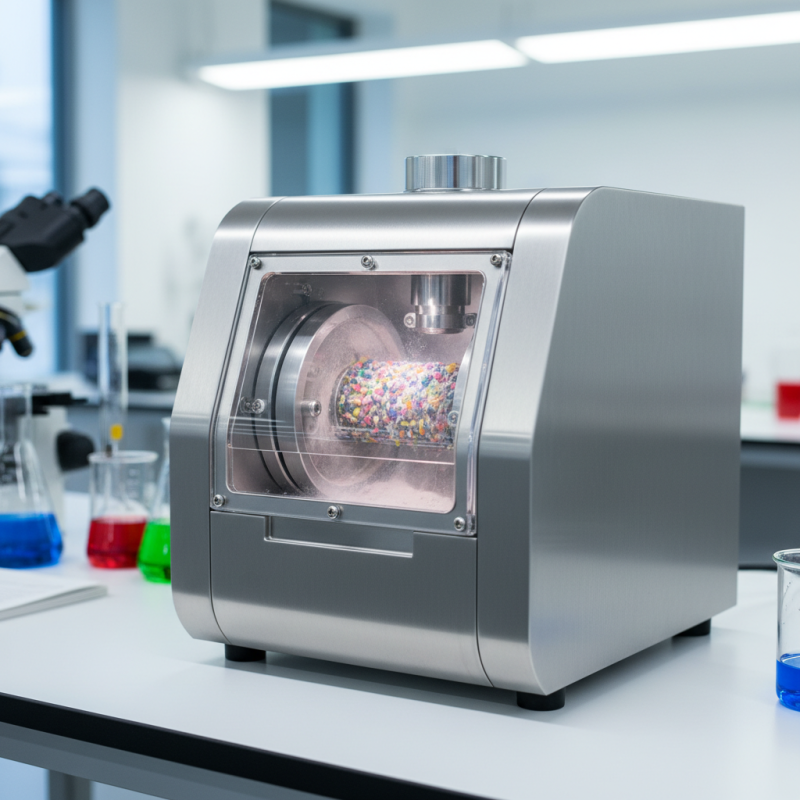

When it comes to material preparation, a laboratory sample pulverizer is an essential tool. This device is designed to grind various materials into fine powders. Whether for chemical analysis or material testing, precision is key. The right laboratory sample pulverizer ensures consistent results and accurate measurements.

Selecting the appropriate pulverizer can be daunting. Many options exist, each with unique features and capabilities. You need to consider factors like material type, desired particle size, and throughputs. By investing in a reliable laboratory sample pulverizer, you enhance your research and testing processes significantly.

Often, people underestimate the benefits of a good pulverizer. It's not just about grinding; it's about achieving specific results. If you choose a subpar option, it can lead to inconsistent quality. This may hinder progress in your projects. Therefore, examining your needs and understanding your options is crucial.

Understanding Laboratory Sample Pulverizers: An Overview

Laboratory sample pulverizers are essential tools for material analysis and research. They provide a means to reduce samples to a fine powder, facilitating accurate testing and experimentation. According to industry reports, the global laboratory pulverizer market is expected to grow significantly, driven by increasing research and development activities. In 2022, it was valued at over USD 500 million, reflecting a steady demand across various sectors.

Understanding the function of these pulverizers is key. They come in various types, including hammer mills and ball mills, each serving specific needs. For instance, hammer mills are efficient for softer materials, while ball mills are preferred for harder substances. However, users must recognize that improper settings can lead to inhomogeneous samples. This inconsistency can adversely impact test results, highlighting the need for user training and equipment calibration.

Moreover, some laboratory settings may overlook the maintenance of pulverizers, leading to inefficiency. Dust buildup can affect performance and safety. Regular cleaning and parts replacement are paramount. Research suggests that neglecting these aspects can reduce operational lifespan by 30%. Acknowledging these challenges is crucial for ensuring reliable data and achieving desired outcomes in laboratory work.

Laboratory Sample Pulverizer Usage Trends

This bar chart illustrates the usage trends of various material types processed by laboratory sample pulverizers. Each bar represents the number of samples processed in units for different material types, highlighting the effectiveness of pulverizers in managing diverse materials in laboratory settings.

Key Features to Look for in a Laboratory Sample Pulverizer

Selecting the right laboratory sample pulverizer can significantly impact your research. Key features should include efficiency, size reduction, and material compatibility. According to a report by Market Research Future, the global laboratory pulverizer market is expected to grow at a rate of around 6% annually through 2025. This indicates the high demand for efficient sample preparation tools.

When looking for a pulverizer, examine its capacity. Many models handle various materials, including minerals and plastics. A device that offers adjustable settings allows researchers to tailor the pulverization process according to their specific needs. Such flexibility can enhance the quality of the final results. However, some users report challenges with consistent particle size distribution. Variability in process execution may lead to subpar outcomes.

Noise level is also crucial. A quieter machine improves the work environment, especially during long sample processing times. However, some users find it difficult to balance noise reduction with performance. They may prefer a louder model that achieves better results, creating a trade-off. Choosing a laboratory pulverizer is a decision that requires careful consideration of these key features to match your laboratory's requirements.

Benefits of Using Laboratory Sample Pulverizers in Various Industries

Laboratory sample pulverizers are essential tools in various industries. They provide precise particle size reduction for many materials. In pharmaceuticals, for example, they ensure uniformity in drug formulations. Consistency is crucial here. A slight variation could affect efficacy. Using a pulverizer can help achieve that critical uniformity.

In environmental testing, these devices play a vital role. Soil and sediment samples need thorough analysis. Pulverizers break down samples for accurate testing. The results are more reliable when samples are homogeneous. However, the choice of the pulverizer must be made carefully. Not all pulverizers are suitable for every type of material.

In the food industry, they help in quality control. Consistent particle sizes in ingredients can lead to better product quality. Yet, one must consider potential cross-contamination risks. Selection of materials for pulverizers should take this into account. Each industry has its unique requirements and challenges. Understanding these can make or break a process.

Types of Laboratory Sample Pulverizers and Their Applications

Laboratory sample pulverizers are crucial for preparing materials for analysis. Different types of pulverizers serve unique purposes. For example, ball mills are ideal for grinding hard materials into fine powders. Their ability to achieve a uniform particle size makes them a favorite in materials science.

Another commonly used machine is the disc mill. This type excels in processing softer materials. It can provide fast results with less heat generation, which is vital for temperature-sensitive samples. However, the selection process can be overwhelming. Each pulverizer varies in capacity and efficiency.

Users often struggle with choosing the right size and speed. The right choice may depend on sample type and desired particle fineness. Sometimes, an underestimated factor like noise level can impact user experience. Making decisions based on incomplete information can lead to inefficiencies. Hence, careful consideration is necessary, as doing it right matters significantly.

Why Choose a Laboratory Sample Pulverizer for Your Needs?

| Type of Pulverizer | Application | Material Range | Key Features |

|---|---|---|---|

| Disk Pulverizer | Grinding of minerals, ores, and concrete | Hard and brittle materials | Fast grinding; adjustable gap; easy to clean |

| Planetary Ball Mill | Material mixing and particle size reduction | Various, including ceramics and alloys | High energy; versatile; multiple jar options |

| Knife Mill | Cutting soft materials like plastics and food | Soft to medium-hard materials | Quick processing; suitable for fibrous materials |

| Hammer Mill | Crushing hard and abrasive materials | Hard materials including minerals and aggregates | High throughput; effective size reduction |

| Vibratory Mill | Fine grinding of materials | Dry and wet materials | Uniform particle size; low noise operation |

Cost Considerations When Choosing a Laboratory Sample Pulverizer

Choosing a laboratory sample pulverizer can significantly impact your research and testing processes. Cost is an essential factor in this decision. Many assume that higher prices ensure better performance. However, that isn't always the case. Some mid-range options may offer comparable features without the hefty price tag.

When evaluating costs, consider the long-term benefits. A cheaper model may break down sooner, leading to additional expenses for repairs. It's also crucial to analyze maintenance and operation costs. Sometimes, a machine that's cheap initially could cost more over time due to inefficiency or frequent malfunctions.

Another factor to reflect on is the potential limitations of budget models. These machines may not handle all materials effectively. If your lab requires diverse sample types, think about future needs. Investing in a reliable machine that meets your current and future demands can save money in the long run. Balancing upfront costs with overall functionality is key.