What is a Ball Screw and Where to Find Them for Sale?

In the world of precision machinery, the ball screw plays a crucial role. Ball screws convert rotational motion into linear motion with high efficiency. They are widely used in CNC machines, robotics, and aerospace applications. According to a recent market research report, the global ball screw market is projected to grow significantly, reaching $5 billion by 2026. This growth highlights the importance of ball screws in modern engineering.

Finding a reliable ball screw for sale can be challenging. Many manufacturers offer various specifications, making it difficult to choose the right one. Quality matters in this industry; even small deviations can lead to performance issues. It's essential to consider factors like load capacity, thread pitch, and accuracy when selecting a ball screw.

Many engineers undervalue the significance of sourcing quality components. Opting for cheap alternatives might save money initially but can lead to costly repairs. Understanding the intricacies of ball screws ensures better performance and reliability in your projects. When searching for a ball screw for sale, thorough research and expert consultations are essential. Taking these steps can prevent future complications and enhance overall efficiency.

What is a Ball Screw?

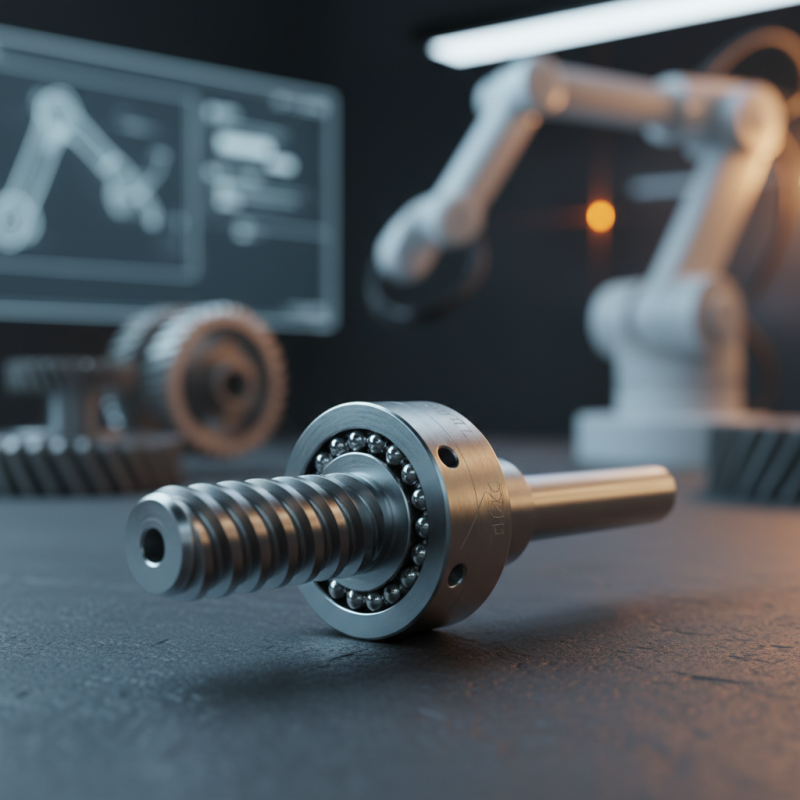

A ball screw is a mechanical device that converts rotational motion into linear motion. It uses ball bearings to reduce friction between the moving parts. This feature significantly enhances accuracy and efficiency in machinery. Research by the National Institute of Standards and Technology indicates that ball screws can have an efficiency of up to 90%. This efficiency is crucial for applications requiring precise movement.

Typically, a ball screw consists of a screw shaft, a ball nut, and ball bearings. The ball nut travels along the screw when rotated, driven by an electric motor or other mechanisms. This setup minimizes wear and extends service life. In manufacturing, it's used in CNC machines, robotics, and other automation tools. Data from the International Federation of Robotics shows that automation in manufacturing increased by 12% in 2022, highlighting the growing demand for precise components like ball screws.

Despite their advantages, issues such as backlash can arise in ball screws. Backlash refers to the slight movement that occurs between the screw and the nut when the direction of motion changes. Additionally, installation and maintenance can be challenging. Ensuring proper alignment and lubrication is vital. As industries push for greater accuracy, the importance of understanding these limitations grows.

How Does a Ball Screw Work?

A ball screw is a mechanical device that converts rotational motion into linear motion. It utilizes ball bearings that circulate between a threaded shaft and a nut. This motion reduces friction and enhances efficiency. In applications like CNC machinery, where precision is vital, ball screws ensure accurate positioning.

When a motor turns the screw, balls recirculate within the nut, creating a smooth, low-friction interface. This design minimizes wear, especially in precision applications. According to industry reports, ball screws can have an efficiency exceeding 90%, a significant improvement over traditional lead screws.

However, not all ball screws perform equally. Variations exist in quality and design. Some screws may show signs of wear after prolonged use, affecting accuracy. Regular maintenance is crucial to sustain performance. It's vital to assess the specific requirements of your application to find the right fit. While ball screws are highly efficient, they must be selected carefully to ensure long-term reliability and optimal performance.

Applications of Ball Screws in Industry

Ball screws play a vital role in various industries. They convert rotary motion into linear motion with great efficiency. This feature allows for precise control in applications like CNC machines, robotics, and conveyor systems. The smooth movement and reduced friction make them ideal for high-speed operations.

In the manufacturing sector, ball screws are essential for automation. They help in assembly lines, reducing the need for manual work. Robotics often rely on them for quick and accurate placement of components. Their durability ensures long-lasting performance, reducing downtime.

Tips: When choosing ball screws, consider the load capacity. It’s crucial for the intended application. Check if they meet the specific requirements of your machinery. Additionally, routine maintenance extends their lifespan significantly. Always look for trusted suppliers to ensure quality.

Ball screws are also widely used in the aerospace industry. They facilitate the precise positioning of parts in aircraft assembly. However, selecting the wrong specification can lead to inefficiencies. It's vital to avoid common pitfalls in their selection and use.

Where to Buy Ball Screws: Retailers and Online Options

When looking to buy ball screws, several options are available. Many people turn to local retailers for immediate needs. Local suppliers provide a hands-on chance to inspect products. This can be beneficial for those new to ball screws. However, local options may have limited variety and higher prices.

Online marketplaces are a great choice for broader selections. Websites dedicated to mechanical components often feature a wide range of ball screws. You can find various sizes, lengths, and materials. It's easy to compare prices and specifications as well. Yet, buyer reviews and ratings should not be overlooked. They can be helpful in understanding product reliability.

Specialized online retailers can also be useful. They often provide detailed technical support. This can guide users in choosing the right ball screw for their project. However, shipping times and costs can vary widely. It might take longer than anticipated to receive your order. Balancing speed and cost is something worth considering.

Factors to Consider When Purchasing Ball Screws

When considering the purchase of ball screws, several factors can significantly impact your decision. It’s essential to evaluate the load capacity. Different applications require screws that can handle specific weights. If your project involves heavy machinery, opt for screws designed for high loads. Look into the materials as well. Steel is common, but other materials could also fit your needs, offering better resistance to wear or corrosion.

Another important aspect is the lead and pitch of the ball screw. This influences the speed and accuracy of the movement. Precise application needs usually require tighter specifications. Sometimes, a shorter lead might be tempting, but it could lead to slower operation. Additionally, the manufacturing quality is crucial. Low-quality screws might save money upfront but can lead to maintenance issues later.

Finding reputable suppliers is equally important. Ensure they provide detailed specifications for their products. Examine testimonials or reviews. This gives insight into their reliability. Maybe a little time spent researching can save headaches in the future. In this competitive market, investing time in choosing the right ball screw can enhance overall performance in your machinery.